Food Processing

Behind-the-Scenes Story of Stainless Steel Chains

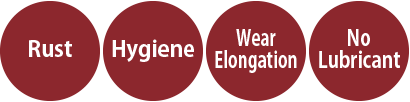

Hygiene issues as chains rust easily in Food Industry

In Food Industry steel chains rust easily as irrigation by water needed due to hygiene issues.

Also another issue is lubricant mix with food as lubrication is needed to avoid rust prevention.

Stainless Steel Chains : Hygiene improved but another task on durability

Stainless steel chains made rust and hygiene issues by the raw material strength as “stainless”.

However, compared with steel chains, stainless steel chains are :

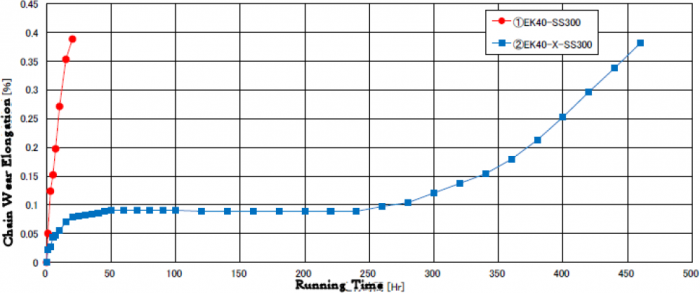

1. Wear Elongation easily

2. Reason for wear elongation easily is due to not being able to lubricate as food hygiene

issues, then frequent replacement caused the work efficiency

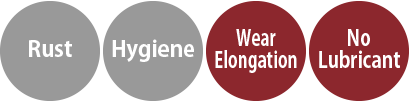

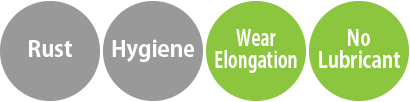

Introducing hygienic and durable Stainless Steel Chains applying our seal chain technology which we have been building by making the motorcycle chains

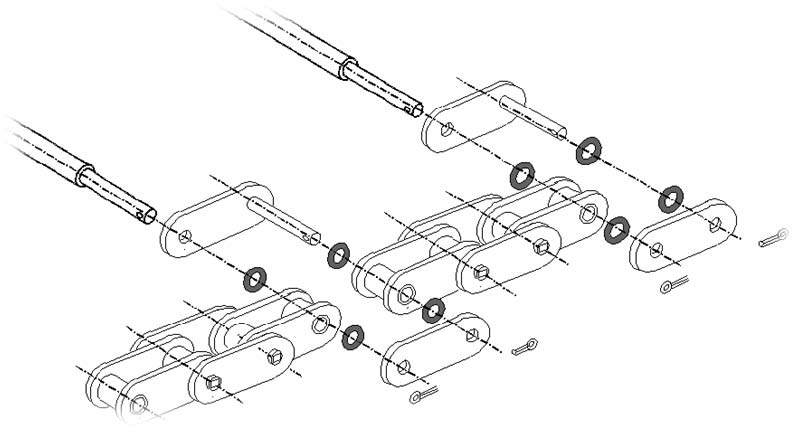

Develop the new stainless steel chains adopting the sealed chain technology

Rubber seal rings seal the grease filled into bushing

Reduce chain elongation by pin wear

Cost Reduction by Improving Production Efficiency(Less Wear Elongation)

Filling and Sealing w/Film Cover from rolled sheet.

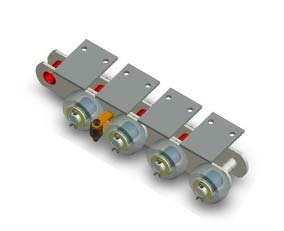

■Performance / Quality Required.

- Tray keep on stopping at the fixed position correctly.

- Filling without any of material leakage.

- Chain Precision

- Enable to decrease wear-elongation

■Expected Advantages

- Stable condition enable to maintain with a less elongation.

- Out of Alignment for filling position can maintain much longer than standard chains.

Mesh Conveyor/Steam & Dry

■Performance / Quality Required

- Reduce possibilities of damages for chains by exceeding tension of mesh belt caused by chain wear-elongation.

- Prevent from wear-elongation by dry-frictional heat caused by ccontinuous heat-wind.

■Expected Advantages

- Blocking Rubber Seal can keep grease between Pin & Bushing and maintain appropriate condition for the roller chain running in a good status.

Conveying Process Products

SteamProcess

Fryer Process

Cooling & Drying Process

Baking Process (small size)

Baking Process (large Size)

Special large size conveyor chains

Pizza Baking (large size)

Special large size conveyor chains

Bucket Conveyor

Oven Process

Boiling Process

Products aluminum can / glass bottle Sterilizing Conveyor

Sterilizer (small)

Sterilizer (can)

Boiling Process

Filling & Packaging Process

Milk Carton Filling Process

Filling & Packaging

Pillow Packaging Process

Products I Material Washing Process

Food Washing Process

Water Bottle Washing

Parts Washing Process